Stainless steel screws are ideal fasteners under most circumstances and are known for their anti-rust and anti-corrosion advantages. The chemical combination of iron with alloy elements like chromium, nickel, molybdenum, and other molecules (in varying proportions) reinforces the strength of iron to form stainless steel with its strength, durability and resistance to heat, cold, water, and other elements. The right screws are as important a part of any build as the woods, metals, cement, plastics, alloys, and other composite materials in any building project - from decks to docks, sheds to schools, and everything in between.

It is essential to discuss your needs with reputable suppliers like Leola Fasteners, to make sure you have the right screw for the right job. Sure, hardware stores have a variety of screws, but do they know exactly what type of screw is needed for decking? Would it be the standard 18-8 or Type 305? Well, it would depend on the type of wood, the climate, how the deck would be attached to the house, and more. Or if you are building a boat dock or a pool, would they be able to tell you the advantages of a Type 316 screw that resists corrosion from saltwater and chlorine? Leola Fasteners can because they specialize in stainless steel fasteners.

Most builder needs for screws and fasteners fit into the 18-8 (Types 300-304 grade stainless steel), Type 305 stainless screws are recommended for decks, Type 316 stainless steel for builds around chlorine, saltwater and other corrosive atmospheres, while Type 410 stainless self-drilling screws are used when extra strength is needed. Each type of stainless steel screw has a different chemical combination that will help keep your build together! Check-in with Leola Fasteners for recommendations on your next DIY or professional build…they are here to help.

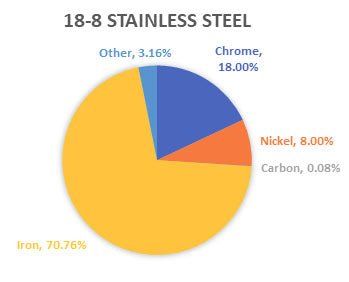

18-8 Stainless Steel (18% Chrome, 8% Nickel, .08% Maximum Carbon)

Standard grade stainless steel, Types 300, 301, 302, 303 for most applications including freshwater environments.

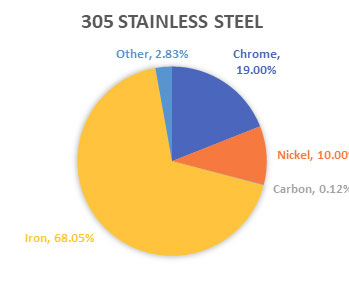

305 Stainless Steel (17-19% Chrome, 8-10% Nickel, .12% Maximum Carbon)

Stainless grade to improve the cold heading attributes, which means the specific screw is more easily shaped to meet specific building needs, with less chance of breakage or galling. Most recommended for composite or wooden decks.

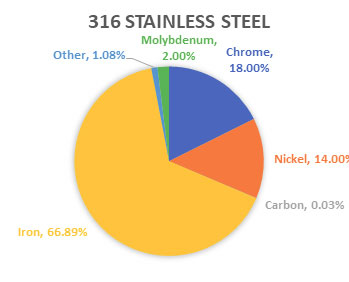

316 Stainless Steel (16-18% Chrome, 10-14% Nickel, .08% Maximum Carbon, and 2% Maximum Molybdenum)

The addition of molybdenum to the stainless alloy makes 316 Stainless screws ideal for building in and around saltwater (and other corrosive) environments like docks, piers, boats, and builds in and around shore towns.

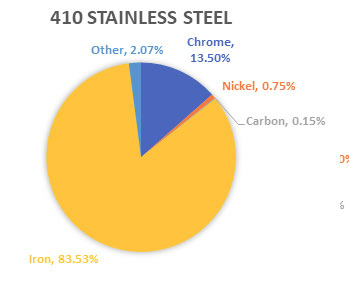

410 Stainless Steel (11.5-13.5% Chrome, .15% Maximum Carbon)

This stainless steel is durable and strong for applications like roofing, siding, and wherever there is a need for self-drilling screws.

Comments (3)

I’ve always used 18-’8’s on my DIY projects, thanks for the info on the other types

410 #10×1 1/2" stainless self tapping screws star head

That’s really nice post. I appreciate your skills. Thanks for sharing.